The standard mechanism for drying filament is to put it in the oven for a while. I started getting strange results with my PETG because I got lazy and left it out between prints. I wanted to fix the issue but wasn't keen about putting plastics in my oven. I wondered about other methods and the silica gel packets came to mind. Those are the little packets that come with shoes and other things and say DO NOT EAT. I was skeptical about the power of these to reverse the absorption that had already taken place, at least not in a timely fashion. Also, I like to tinker and wanted to experiment with weird ideas.

I like to sous vide and had recently gotten a food vacuum sealer with an attachment for sucking the air out of wine bottles. I could seal the filament spools in a vacuum bag with some desiccant but I felt like it would work better if I could get closer to a proper vacuum. I didn't want to invest in a high-grade vacuum chamber and pump for an experiment. I started looking around and found the FoodSaver Quick Marinator; a rigid container with a valve for the hose that connected the vacuum sealer to attachments.

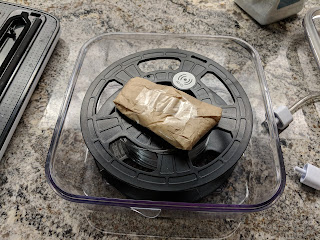

Here's my setup:

- Off-brand food vacuum sealer

- The FoodSaver Quick Marinator

- The vacuum sealer attachment hose

- Coffee Filters

- Flower desiccant powder

The flower desiccant powder is the same material as the silica gel packets you can get but it's very fine, providing a higher surface area, and they're trivial to renew.

I put 5 (arbitrary) tablespoons of desiccant powder into a coffee filter, fold it up, and tape it closed so the powder can't easily escape.

I put my filament spool into the marinator, drop my desiccant pack on top and put the lid on the with tabs on the same side.

Then, suck the air out. I run the pump until it shuts off. Wait a few seconds, and repeat. I go through about three cycles of this. After the pump has shut off, ensure the pump isn't warm; you don't want to ruin your pump by overheating it.

Finally I ensure the valve is closed before removing the hose.

Surprisingly, this worked. My next round of PETG printing produced a nice, smooth finish. I've taken to storing the spools with one of my homemade desiccant packets in a small Space Saver bag and vacuum the air out. It doesn't look like they sell just the small bags and the medium and larger are grossly too large for a filament spool.

It's important to note that so far I've only done this desiccating process on Dremel filament spools which are 0.5kg. As you can see in the picture above these spools just fit in the quick marinator. Larger spools probably won't fit, loose filament can depending on how much you want to stuff in there. When I get larger spools I'll probably have to come up with another mechanism.